if any one would like to donate to this project *caugh *caugh

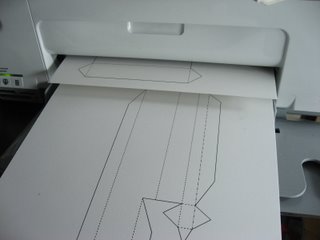

simply amazing a printer like machine that cuts out paper patterns.

simply amazing a printer like machine that cuts out paper patterns.

Parsons School of design thesis 2007

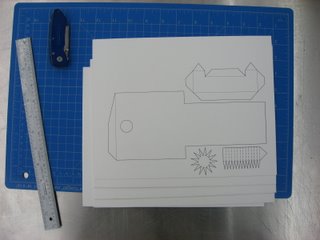

so i created another model in solidworks that i hoped would work. Then created the flat patters in pepakura (see earlier posts for more details on this) Then i began to cut down 18x24 bristle board to 8x11 sheets.

so i created another model in solidworks that i hoped would work. Then created the flat patters in pepakura (see earlier posts for more details on this) Then i began to cut down 18x24 bristle board to 8x11 sheets.

paper engineering kit, just found this one very similar in concept of construction.

paper engineering kit, just found this one very similar in concept of construction.

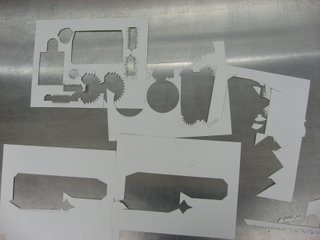

so the way the patterns were created the size of the tabs to attach the gears together don't work with cardboard. There is just not enough material to keep the layers from ripping. however this just may be a scale issue but the next round of tests will be to look at alternative methods for construction.

so the way the patterns were created the size of the tabs to attach the gears together don't work with cardboard. There is just not enough material to keep the layers from ripping. however this just may be a scale issue but the next round of tests will be to look at alternative methods for construction.

This is the start of the new logo i am developing for them for this years competition.

This is the start of the new logo i am developing for them for this years competition.