Since the last model i had 2 new major improvements. First using Blocks in solidworks. This really helps my ability to engineer parts and know if they are going to work as a solid form. Secondly i decided to shove some bristle board into my printer and see what happens. The printing worked with out a hitch so no messy transfers of patterns. Next i need to look more at clear ways to help instruct the use of these patterns and construction safety.

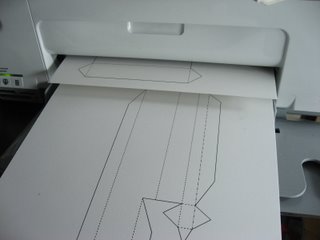

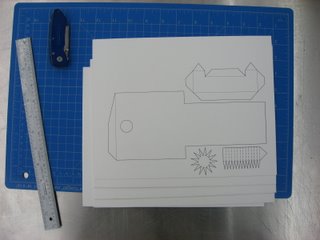

so i created another model in solidworks that i hoped would work. Then created the flat patters in pepakura (see earlier posts for more details on this) Then i began to cut down 18x24 bristle board to 8x11 sheets.

so i created another model in solidworks that i hoped would work. Then created the flat patters in pepakura (see earlier posts for more details on this) Then i began to cut down 18x24 bristle board to 8x11 sheets.

so crossing my fingers it went though my printer w/ out any trouble or jamming.

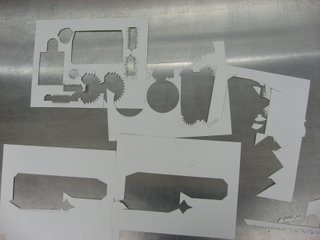

with the patterns in hand i started cutting them out. However printing on 8x11 with out tiling is defiantly a challenging design constraint. Now parts have a serious size restriction making sure that the parts do not become too small or complex to handle is becoming a serious concern.

Lots of small connections and parts that need to be simplified a bit in how the patterns are made

Also i have been watching the amount of waste from the patterns to minimize scraps if recycled card board cant be used for intricate parts.

0 Comments:

Post a Comment

<< Home